|

|

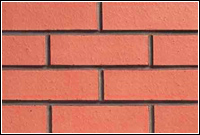

| wire cut bricks |

|

The use of optimum quality materials in the manufacturing of the Plain Wire Cut Bricks are of optimum quality that ensures notable features like high durability and resist nature to adverse conditions.

|

|

|

Available sizes

9 X 4-5 /16 X 3 ( in inches )

Brick Usage - There are three main categories of use, and both pressed bricks or wire-cut brick types are used in all three categories. Facing brickwork - is the visible decorative work.

Engineering brickwork - often seen in bridges and large industrial construction but may also be hidden in ground works where maximum durability is required, e.g., in manhole construction.

Common brickwork - is not usually seen and is used where engineering qualities are not required; below ground in domestic buildings and internal walls, for instance. Wire-cut - bricks may be laid either way up but some types of wire cuts have a textured (combed) face, creating folds in the face of the brick, which is directional. It is advisable to lay these bricks with the folds hanging downward to maximize the weathering characteristics of the brick.

Wire cut bricks are made by extruding or forcing clay to form a long column, which is then wire cut into evenly shaped rectangular bricks.

- Better Insulation.

- More Strength.

- Sharp and even edges ensure saving in mortar costs.

- Faster Installation - Saving time and labor.

- Better Endurance against elements of nature - Rain Sunshine and Wind.

|

|

|

|

|